In industrial production, different application scenarios have different requirements for light sources. According to actual application scenarios, we generally divide light sources into 11 types for induction.

1. Ring light source:

The light output angle value is between 0°-90°, 0°~45° is a low-angle ring light source. Current application cases include glass dust scratch detection, metal frame scratch detection, smooth surface scratches, and damage detection to highlight the object wheel. Contour, scratch, and damage effect 60-90° light emission angle concentrates on the surface of the measured object, highlighting the different characteristics of the surface of the object. Application cases include: inductive tin surface detection, character detection, pins of different data interfaces Needle detection, and flat inkjet detection. Provide different irradiation angles, different color combinations, and highlight the three-dimensional information of the object. The high-density LED array, high brightness, and a variety of compact designs save installation space and solve the problem of diagonally irradiated shadows. The optional diffuser plate guides the light and spreads the light evenly. Application fields: PCB substrate detection, C component detection, microscope lighting, liquid crystal correction, plastic container detection, integrated circuit printing inspection

2. Coaxial light source

High-intensity and uniform light passes through the beam splitter and is coaxial with the lens, and special materials are used to suppress ghosting caused by reflections. Improve imaging clarity. It is suitable for the scratch and printing detection of the tested instant noodles with high reflectivity. Application cases include: laser marking characters, two-dimensional code recognition, scratch detection on the surface of objects with high reflectivity.

3. Bar light source

This light source is characterized by its flexible and compact size, which can be adapted to different positions. It is mainly suitable for detecting larger square structures with obvious effects. Current application cases include cracks and QR code reading. Edge detection, screen printing text detection.

4. Four sides adjustable light source

Four independently adjustable bar light sources can independently control the brightness, flexible installation, high brightness and high precision lighting. Field of application: Inspection of four-sided pin flat packs, QR code reading ceramic packaging surface inspection.

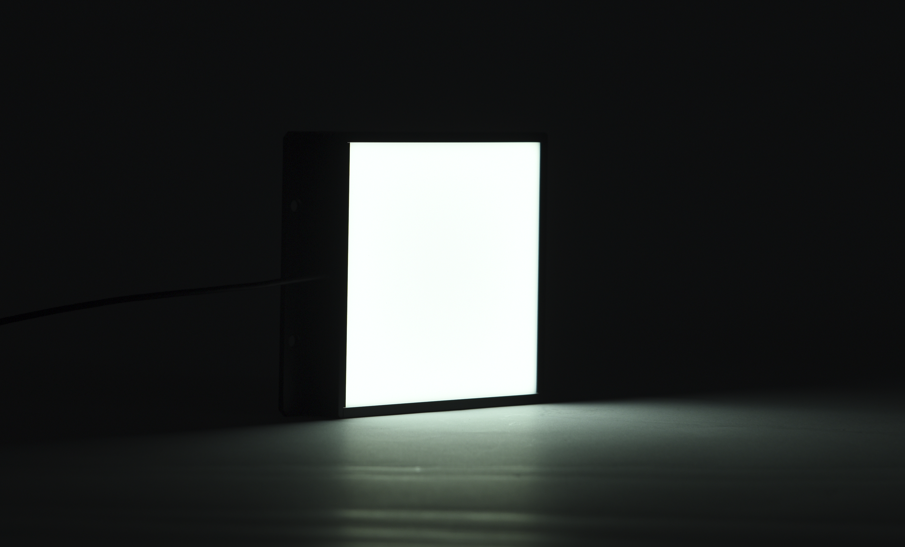

5. Bottom back light The bottom-emitting standard back light can be applied to the microscope stage, highlighting the outline of the measured object and providing high-brightness back lighting by a high-density LED array. Applied to the detection of burrs, stains and scratches on transparent objects.

6. Square shadowless light source:

Suitable for rectangular and irregular measured objects, providing a rectangular field of view. Application cases: battery board disconnection detection, mobile phone cotton sticking, film position edge correction, one-dimensional, two-dimensional code recognition.

7. AOI dedicated light source

It has the characteristics of high brightness, good uniformity, and high spatial resolution. Three sets of independently controlled ring light sources illuminate the circuit board at different angles of high, medium and low, which can well highlight the characteristics of component electrodes, pads, solder joints, etc. on the circuit board that do not have gradients. Application fields Multi-level object inspection, plug-in solder joint inspection, placement, solder inspection.

8. Point light source

The unique concentrating effect (light guide column) is used to achieve uniform illumination. Applications include liquid crystal glass line detection, scratch detection on the glass surface, and character detection at the bottom of the plug.

9. Linear light source

Linear light, high-intensity light lighting, current application cases: detection of bumps, scratches, and stains on the surface of mobile phone shells. Use special lenses to make the light shoot out linearly, and keep it uniform and smooth.

10. Dome shadowless light source

After the light is reflected by the spherical diffuser, it is smooth and evenly irradiated on the measured object. It is suitable for dry objects with uneven and reflective surfaces. Application cases for curved surface, surface bump, arc detection. Metal, glass reflective surface detection.

11. Parallel light source

The light propagates in a straight line, with high brightness and uniform brightness. It is mainly used for high-precision detection. It can be used as a backlight when used in conjunction with a telecentric lens.

OSTHK are focusing on provide any kind of light source and light source solution. By the helping from professional product manager, we can always fulfill customer's demand and have a good review.